How to increase the Furnace load up to +100 %

Figure 1: Three CFC Fixture or Rack Design levels by High Temperature Concept

Please note that Carbon Fiber reinforced Carbon or CFC is still an outstanding, unreached material. Some details see Newsletter #1. The main 3 material properties which make this material so outstanding and recommend it as a Fixture Material are (CFC Sigrabond Performance ® compared to heat resistant cast austenitic steel like ASTM A297-HK at 20 and 1,000 oC):

1. Low density of about 1.5 compared to 7.8 to 7.5 g/cm3

2. Low C. T. E. of about -0.5 to 0.8 compared to 11 to 18 x 10-6 K-1

3. Extremely high specific strength of about 200 to 233 compared to 65 to 11 N / m g

But, why is it still a great challenge for technicians and engineers designing ingenious Fixtures for commercial or captive heat treaters? An attempt at explanation is that there are some contradictory requirements for material developers and designers on the one hand, and users in industry in the rough heat treatment area and its surroundings on the other hand.

Unlike many competitors, we worked for many years in the user industry in responsible positions and/or went to many customers with heat treatment workshops. Many Fixture designs were successfully realized for our customers, mainly in the Industries of Tooling, Automotive, Electronics, or Aerospace.

The key to success or “the needle in the haystack” is the just mention combination of knowledge and experiences. Mainly with the aim reducing work piece distortion most effective, in some cases with the result of reduced hard machining.

Another unique feature is that the President and founder of High Temperature Concept TM Dr. Jorg Demmel wrote his doctoral thesis just on this field over “Scientific aspects of the development of new workpiece carriers for high temperature processes made of fiber composite ceramics CFC and other high temperature materials”.

The consequence is, that of course our aim is to be best-in-class, means, compared to Figure 1, our approach is design level III. Or, in other words, our Fixture design pays off most! Compare Figure 2.

Figure 2: Design levels and competitors by High Temperature Concept

As proof of the written passages above, we would like to introduce just two CFC Fixture applications, both of which have been successful in the industry for over 15 years and pay off.

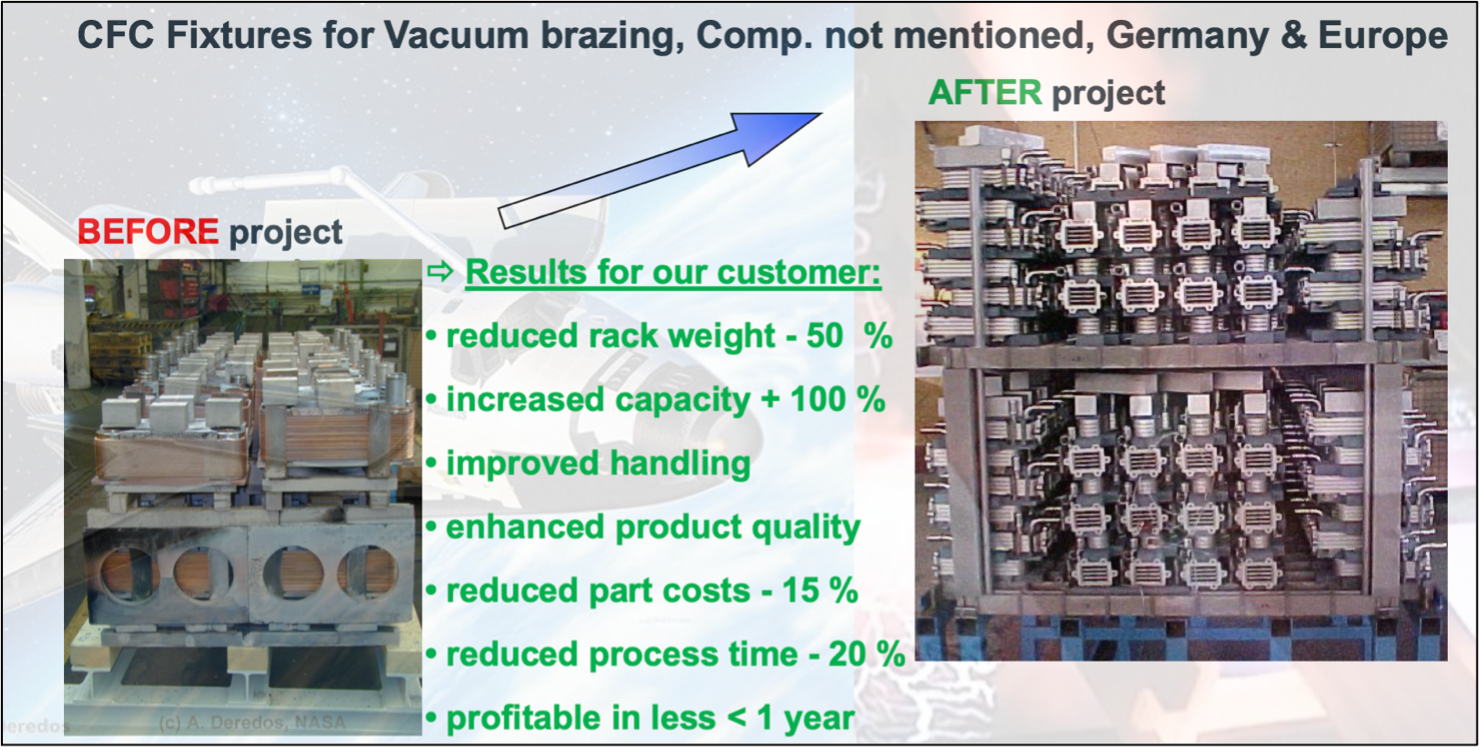

Figure 3 shows CFC-Fixtures for Brazing of heat exchangers in a vacuum process.

Figure 4 shows CFC-Fixtures for Allen keys in an Annealing process in an atmosphere process with oil quenching.

Figure 3: Level II CFC Fixture Application for Brazing, Modine Europe

Figure 4: Level III CFC Fixture Application for Annealing incl. oil quenching, Wiha

Figure 5 shows the main advantages of CFC Fixtures (green columns) compared with state-of-the-art cast steel Fixtures (red).

This is paragraph text. Click it or hit the Manage Text button to change the font, color, size, format, and more. To set up site-wide paragraph and title styles, go to Site Theme.

Figure 5: CFC Fixture and Rack Advantages (min./max. values of the bars depending on customer situation and investment volume; by experience; © High Temperature Concept TM, Dr. Jorg Demmel)

Last but not least, CFC Fixtures with low weight and C.T.E. open a new perspective of heat treatment integration in the process chain between soft and hard machining. Automatic part handling can be reached effectively mainly in large-scale productions like in the automotive industry. It is reported not only by the author, but as well in /1/, that in some cases “hard machining can be eliminated completely”. This is explained by the just mentioned CFC properties and its high thermal shock and chemical resistance, and the high dimensional accuracy and shape stability of CFC Fixtures, Racks and Trays, which results in a much better process control. An increased process reliability with less product distortion is not only reported by the author for many CFC Fixture applications of heat-treated precision parts, but also mentioned for the case hardening of large surface gear parts with low-pressure carburizing (LPC) combined with high-pressure gas quenching (HPGQ) in /1/.

CFC Fixtures play an important role in controlling distortion, increasing net load, reducing multiple workpiece handling, and decreasing fixture life cycle costs. Therefore, overall manufacturing costs can be significantly reduced.

Ask for the difference!

It pays off soon.

Get your custom quote today Request Quote.

Contact Us:

info@High-Temperature-Concept.com

www.high-temperature-concept.com

Sources:

J. Demmel, dissertation „ Scientific aspects of the development of new workpiece carriers for high temperature processes made of fiber composite ceramics CFC and other high temperature materials “, TU Freiberg, Germany, 2003, and

Dr. J. Demmel oral presentation „Advanced CFC

-Fixture Applications,

their scientific challenges and economic benefits“,

30th Heat Treat,Detroit, Michigan, 15th October 2019, and

/1/

R. Terjung: CFC-Fixtures – Quality fixturing for vacuum heat treating, 4-2016, in: Heat processing, p. 73-77